LIFTCHEM-UV Curing Raw Materials, Pharmaceutical Intermediates

Diethyltoluenediamine (DETDA), CA number: 68479-98-1 is an organic synthetic intermediate consisting primarily of a mixture of two diethyltoluene-2, 4-diamine isomers, 3, 5-diethyl-toluene-2, 4-diamine and 3, 5-diethyl-2, 6-diamino-toluene (3, 5-diethyl-2, 6-diamino-toluene). 5-diethyl-toluene-2, 6-diamine)

Physical properties: Light yellow to colorless transparent liquid with ammonia flavor, slightly soluble in water, soluble in alcohol, ether, ketone and other polar organic solvents.

Chemical properties: The two amino groups in the diethyltoluene diamine molecule (DETDA) are basic and can react with acids to form salts. Its derivatives include N, N' -bis (2-hydroxyethyl) diethyltoluenediamine, N, N' -bis (2-methoxyethyl) diethyltoluenediamine, etc.

Uses: Diethyltoluene diamine (DETDA) has a wide range of applications in chemistry, medicine, pesticides, dyes and other fields. As polyurethane raw material, it can be used to prepare high-performance polyurethane elastomers, coatings, sealants, etc. As an antioxidant and chain extender, it can be used to modify and cure polymer materials such as polyurethane and epoxy resin. It can also be used as lubricant and industrial oil.

Production method: Preparation of Diethyltoluenediamine (DETDA) usually involves the reaction of toluene with ethylamine to obtain N, N' -diethyltoluenediamine, which is then purified by distillation to obtain a high purity product.

Risk: Diethylmethylenediamine (DETDA) is moderately toxic and can be poisoned by prolonged exposure or ingestion. It is strongly irritating to the skin and eyes and may cause burns and severe inflammation.

With the development of polyurethane, diethyltoluene diamine (DETDA), as a liquid steric aromatic diamine chain extender, was industrialized and widely used in the early 1980s. Due to its low viscosity, uniform dispersion, high chemical activity and thorough reaction, DETDA can be directly used as chain extender. DETDA is a very effective polyurethane elastomer chain extender with fast reaction time, short release time, high initial strength, product resistance to hydrolysis and heat. DETDA is particularly suitable for use on RIM(reactive injection molding) and SPUA(sprayed polyurea elastomers), but can also be used as an aromatic diamine hardener for polyurethane elastomers and epoxy resins. DETDA is used in polyurethanes to improve product strength and hydrolysis resistance. It reacts with polyurethane prepolymers several times faster than DMTDA and about 30 times faster than MOCA, greatly increasing product productivity and making it possible to industrialize polyurethane products of large size and complex structure. The fast reaction rate of DETDA with isocyanates is also particularly suitable for solvent-free, fast solid coatings.

DETDA can also be used as epoxy and alkyd resin hardener, rubber oil antioxidant, dye, pesticide intermediate and is a versatile chemical product.

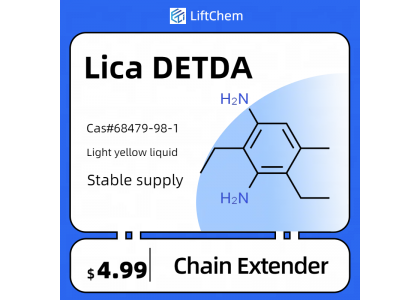

Lica DETDA

Basic elements of product

Appearance: Light yellow to amber clear viscous liquid

Cas No: 68479-98-1

Packing: Net weight 200KG/ galvanized iron drum, 1000KG/IBC drum

Chinese name: Diethyltoluene diamine, curing agent, chain extender

English name: Diethyl toluene diamine, DETDA

Molecular weight :178.28

Molecular formula: C11H18N2

Boiling point :301.4°C at 760 mmHg

Packing: Net weight 200KG/ galvanized iron drum (16 tons /20 feet cabinet), 1000KG/IBC drum (18 tons /20 feet cabinet) or 23 tons ISOTANK.

Storage conditions: indoor, ventilated, away from light, avoid high temperature.

Lica DETDA can completely replace foreign Arxada Lonzacure 80 and 100.

LiftChem works deeply with the leading DETDA manufacturers in China to ensure product quality and stable supply. After years of efforts, the current factory capacity has reached 3000 tons/year, the products are exported to South Korea, Japan, the United States, Brazil and the Middle East region, widely praised by the customers. We will plan further capacity expansion to meet the growing downstream demand.